How Is the Stone Cage Net Installed?

Posted By ANPING HAOCHANG WIRE MESH MANUFACTURE CO.LTD on 2020-06-16 1:21 AM

Description

Gabion is made of low carbon steel wire with high corrosion resistance, high strength and high ductility, or above PVC coated steel wire. The box structure made of this net is stone cage. According to ASTM and EN standards, and according to engineering design requirements, the diameter of the low-carbon gabion wire used varies. Generally in the range of 2.0-40mm, the tensile strength of the gabion wire is not less than 38 kg≤m~2, the weight of the metal coating is generally greater than 245 g/m~2, and the diameter of the edge line of the gabion net is generally larger than the net line. The length of the two-wire stranded part shall not be less than 50 mm. In order to ensure that the metal coating and PVC coating of some steel wires are not damaged.

Steel wire Gabions can be used for slope protection, foundation pit support, mountain rock net spraying, slope greening and railway highway isolation protection, and can also be made into cage nets and mesh pads, which can be used for rivers, embankments and sea The erosion protection of dikes can also be used for the protection of reservoirs and interceptor cages.

The most serious causes of water flow disasters are generally erosion and destruction of river banks, resulting in floods, causing a lot of loss of life and property and a lot of soil erosion. Therefore, when dealing with the above problems, applying ecological grid structure has become one of the good solutions , Which can protect the banks of the riverbed for a long time.

1. When installing the gabion mesh, the wrong gabion mesh joint should be set to avoid longitudinal penetration of the joint.

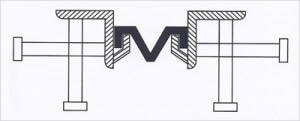

2. The four sides of the gabion net will stand up, and the adjacent edges will be locked with a tie line. The tie line will surround the two overlapping frame lines (when stitched) and the double folded edge of the cage to avoid galvanizing Damaged, the pitch does not exceed 500 mm.

3. When installing the gabion net on the completed bottom net, fix it on the bottom gabion net with wires along the lower edge of the newly installed galvanized gabion net, and connect the adjacent same layer of gabion net , This constitutes the connection of galvanized gabion nets.

4. In the construction of the same level of the unit project, the gabion nets should be filled with pebbles only after they are all in place. To prevent the deformation of the gabion net, the height difference between two adjacent gabions should not exceed 35 cm.

5. Before installing the gabion net, the bank slope and ground should be properly repaired before installation, and the original shape of the bank slope should be kept as much as possible, but no obvious uplift and depression should appear.

6. The rock fill in the cage can be selected on the beach. Its compressive strength should meet the design requirements. The size of the pebbles should be between 8 and 20 cm. Straight shape.

7. After filling with stone material, close the lid, and then twist the overlapping frame wires with a tether spirally, the pitch should not exceed 50 mm.

8. Fill the upper part of the masonry cage retaining wall with 10 to 15 cm of humus for plant growth

Gabion baskets suppliers remind you that after installation, attention should be paid to later maintenance and repairs.

Tags: custom gabion, gabion cages, gabion, steel wire gabions

For more information, please Click Here